vickers hardness test slideshare|vickers hardness chart : factory The document discusses hardness testing methods. It describes how hardness is defined differently depending on one's field, such as resistance to indentation for metallurgists. The main hardness tests described are static . Videos da Martina Oliver peituda. Assistir Onlyfans gratis no Buceteiro.com Beiçola do privacy mostrou os peitos grandes. Martina Olvr (@martinaolvr_) novinha linda e maravilhosa de apenas 20 aninhos de idade, gaucha, ariana e apaixonada por tatuagens.

{plog:ftitle_list}

Resultado da Bring your best ideas to life,together. The online diagramming tool for teams who want to achieve more. Try it free. Create diagrams online with a .

The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves pressing .The document discusses hardness testing methods. It describes how hardness is .The document summarizes the results of a micro Vickers hardness test. The test .Hardness is a material's resistance to plastic deformation from external forces. .

The document discusses hardness testing methods. It describes how hardness is defined differently depending on one's field, such as resistance to indentation for metallurgists. The main hardness tests described are static . The document summarizes the results of a micro Vickers hardness test. The test was performed on samples with a load of 50 gf and dwell time of 15 seconds. The test measured the hardness of different phases using .The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

It begins by defining hardness and describing the three main types of hardness tests. It then focuses on the Vickers hardness test, explaining the development of the test in 1924 and the key principles such as using a diamond pyramid . • Vickers hardness is a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. • The indenter employed in the Vickers test is a .Vickers Test Presentation - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The Vickers hardness test uses a diamond indenter in the shape of a square-based . Hardness is a material's resistance to plastic deformation from external forces. There are several common hardness tests used to measure this property, including Brinell hardness testing, Rockwell hardness testing, and .

is passing the drivers test hard

2. Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of .

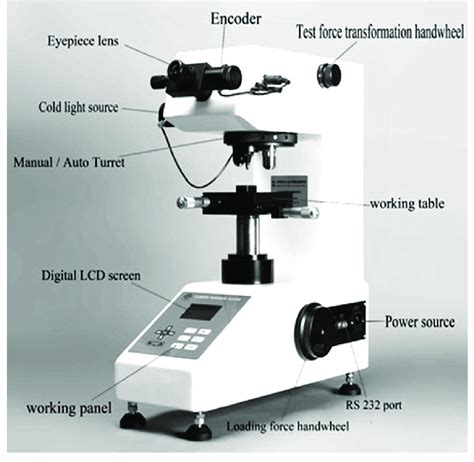

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .13. • 1822: Friedrich Mohs (Ger) - A ten-point scratch hardness Mohs scale. • 1900: J. A. Brinell (Swe) - A ball indentation / dent dia size Brinell Hardness. • 1920: S. R. Rockwell (US) – Minor, major load / dent depth Rockwell . The micro Vickers hardness test uses a diamond indenter with a 136-degree pyramid shape to make indentations on a material under precise loads. The load is applied for 10-15 seconds, leaving a square-shaped impression. The two diagonals of the impression are measured under a microscope and used to calculate the Vickers hardness value according .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

Tinius Olsen is the leading specialist manufacturer and supplier of static tension and/or compression materials testing machines. Tinius Olsen machines are designed for use in many industries including research and quality control to measure material’s strength and performance. Using Tinius Olsen equipment it is possible to perform tests on raw materials and finished .

Micro hardness testing involves forcing a diamond indenter with a specific geometry into the surface of a test piece under a small load, then using a microscope to measure the resulting indentation to determine the hardness; there are three main types of tests that differ by the indenter shape and how indentation size is measured; micro hardness testing is useful . 14. Knoop Test (Micro Hardness Test) Various micro hardness tests have been developed for application where it is necessary to determine the hardness of a very precise area of material, or where the material or surface layer is exceptionally thin. Special machine have been developed for this purpose. The location for this test is select in the high magnification. A . 1. Universitas 17 Agustus 1945, Surabaya, 2014 Rohmad Putra 411306092 1 Nama : Rohmad Putra Nbi : 411306092 Kelas : C Rumus Dari Metode Hardness Test Metode Brinnel, Rockwell, Vikers Dan Micro Hardness 1. Metode Brinnel (HB / BHN) Pengujian kekerasan dengan metode Brinnel bertujuan untuk menentukan kekerasan suatu material .

VICKERS HARDNESS TEST • Vickers Hardness is an alternative to the Brinell method to measure the hardness of materials. • The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. 6. = 2 [ − √ − Where: P ; is the test load [ kg] D ;is the diameter of the ball [mm] d ; is the average impression diameter of indentation [mm] The diameter of the impression is the average of two readings at right angles and the use of a Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured Brinell hardness number .

11. About the experiment The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to15 seconds. The two diagonals of the indentation left . The followings are the most common hardness test methods used in today’s technology: (1) Rockwell hardness test (5) Knoop hardness (2) Brinell hardness (6) Shore (3) Vickers (7) Mohs Hardness (4)Barcol Hardness Brinell Hardness The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . VICKERS HARDNESS TEST It is a micro hardness tester and used to measure hardness of soft and hard materials alike, particularly used for extremely hard surfaces. The surface is subjected to a standard pressure .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .

4. Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. Vickers Hardness Test: Pyramid shape indenter . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. 2. Knoop diamond Vickers diamond pyramid 3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements. 12. ROCKWELL HARDNESS TESTS: - The Rockwell hardness test relies on a specified load and the size of the indentation or penetration made to determine the hardness value. Rockwell hardness tests involve selecting the magnitude of the load to apply based on the suspected hardness of the specimen. Rockwell B (ball) used for soft materials. Rockwell C .

3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-termined force, into the surface of the material under test and to measure the diagonals of the resulting impression after removal of the force. Jominy end quench hardenability test - Download as a PDF or view online for free. Submit Search. . And finally the Rockwell or Vickers hardness values are plotted versus distance from the quenched end. Hardness versus distance from the quenched end Hardness, HRC Distance from quenched end The Jominy Test data illustrates the effect of .

• Brinell Hardness Test • Rockwell Hardness Test • Knoop Hardness Test • Vickers Hardness Test 05 Types of Hardness Test 6. • Based on indentation depth • Applied load 100-150kg • Brale angle: 120 degree • Brale radius: 0.2mm 06 Rockwell Hardness Test

is passing the driving test hard

Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials . 3. PRAKTEK UJI BAHAN D4 TEKNIK PERPIPAAN POLITEKNIK PERKAPALAN NEGERI SURABAYA Lanjutan tabel 2.1 Konversi Hardness ke Tensile Strength Tensile Strength(MPa) Brinell Hardness (BHN) Vickers Hardness (DPH) Rockwell Hardness (HRB) Rockwell Hardness (HRC) 1290 380 400 40.8 1320 390 410 41.8 1350 399 420 42.7 1385 409 .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.

vickers hardness testing machine diagram

Resultado da Aviatrix game: features, rules, strategies ⚡ Get registration bonuses 🎁 Winning strategies and game rules on our website

vickers hardness test slideshare|vickers hardness chart